Learn More About the Tiltrotator

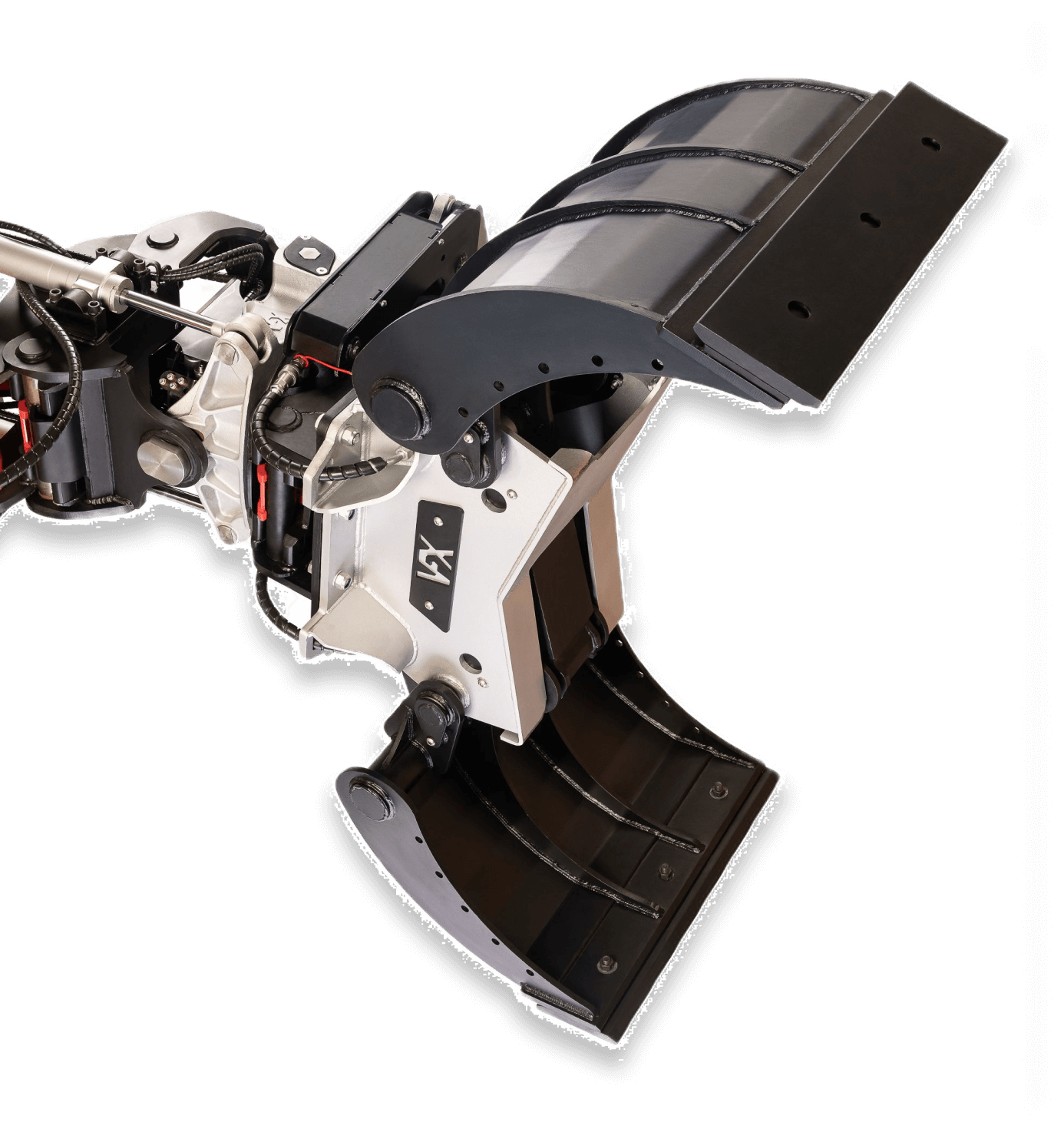

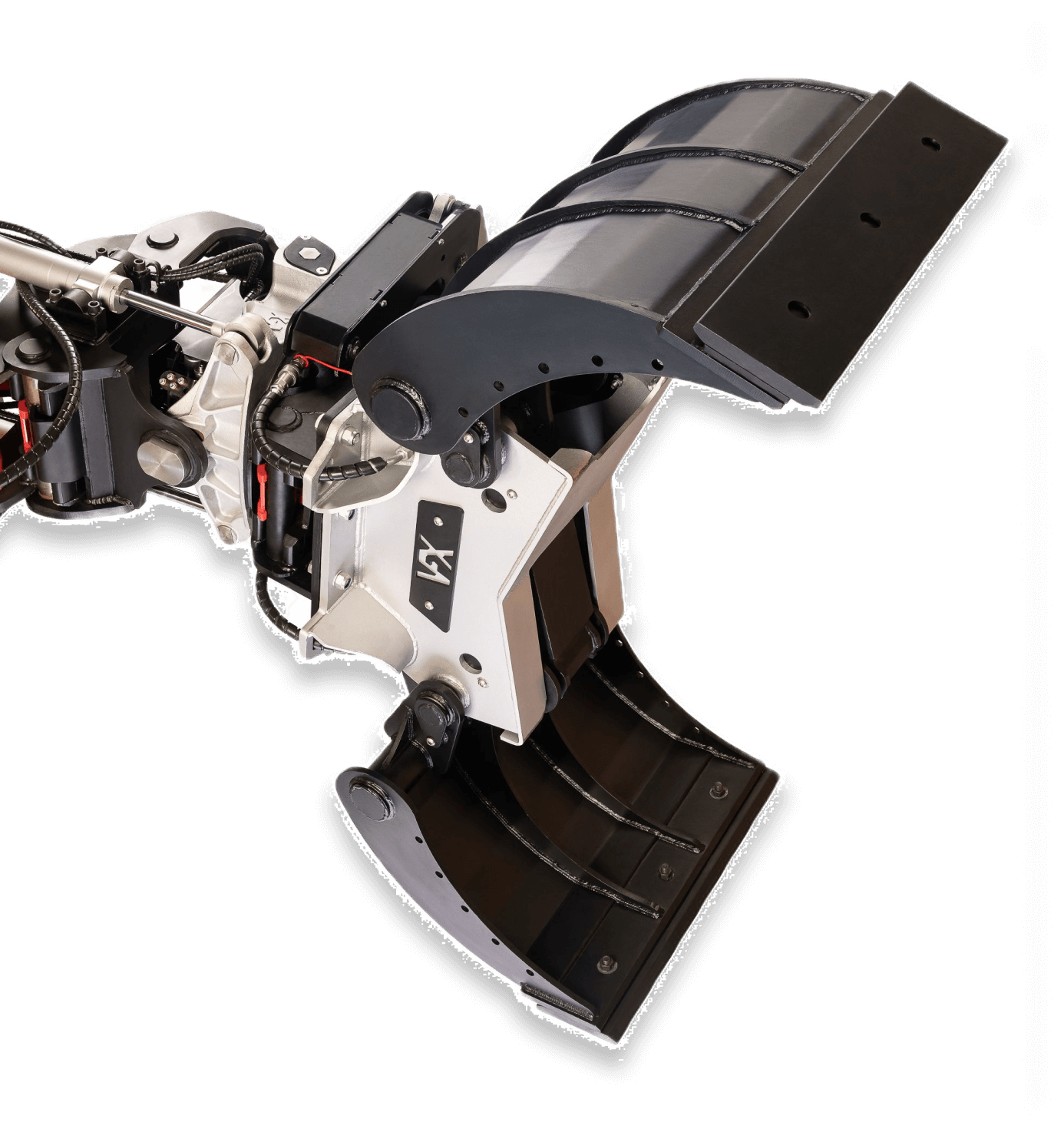

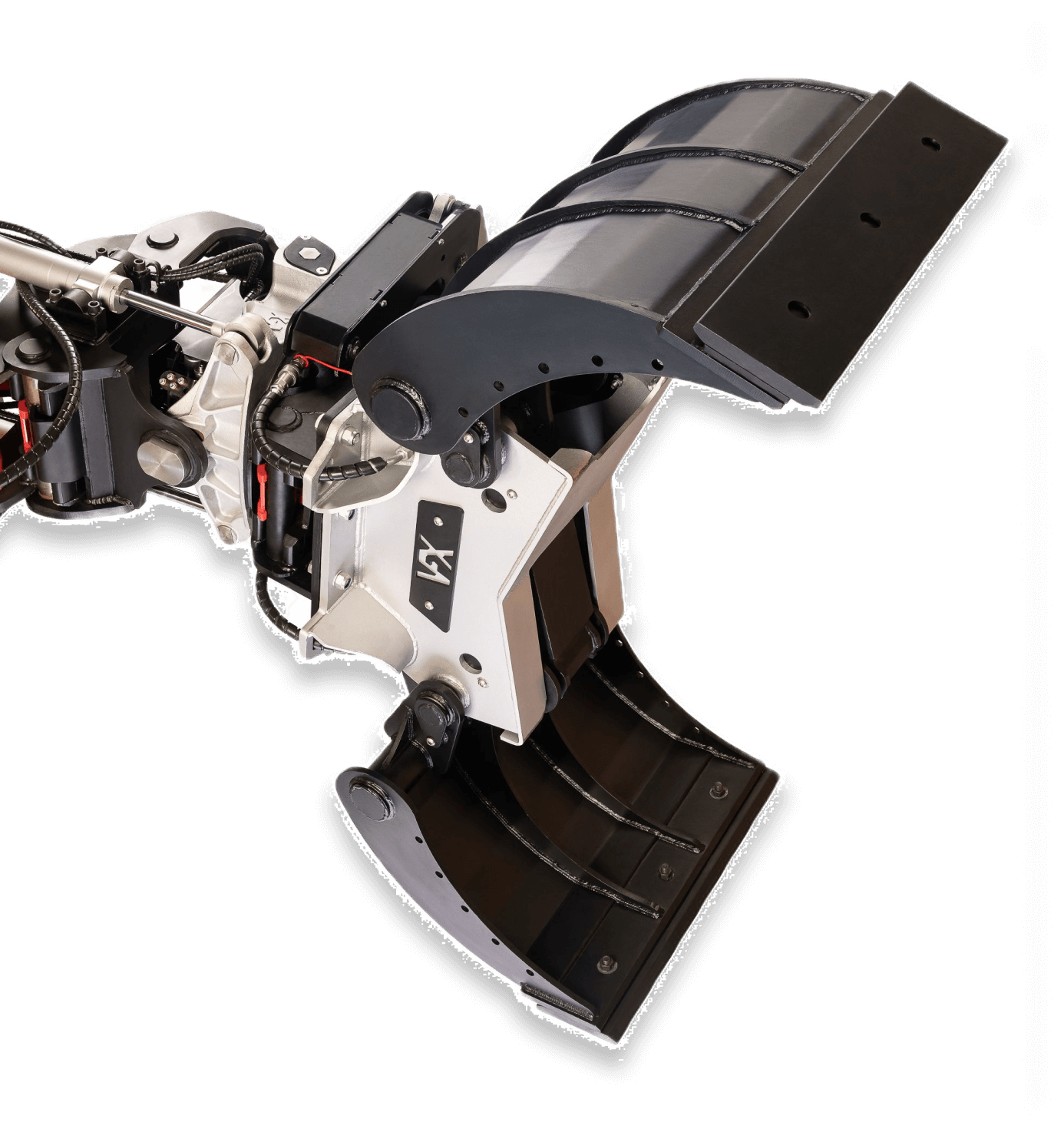

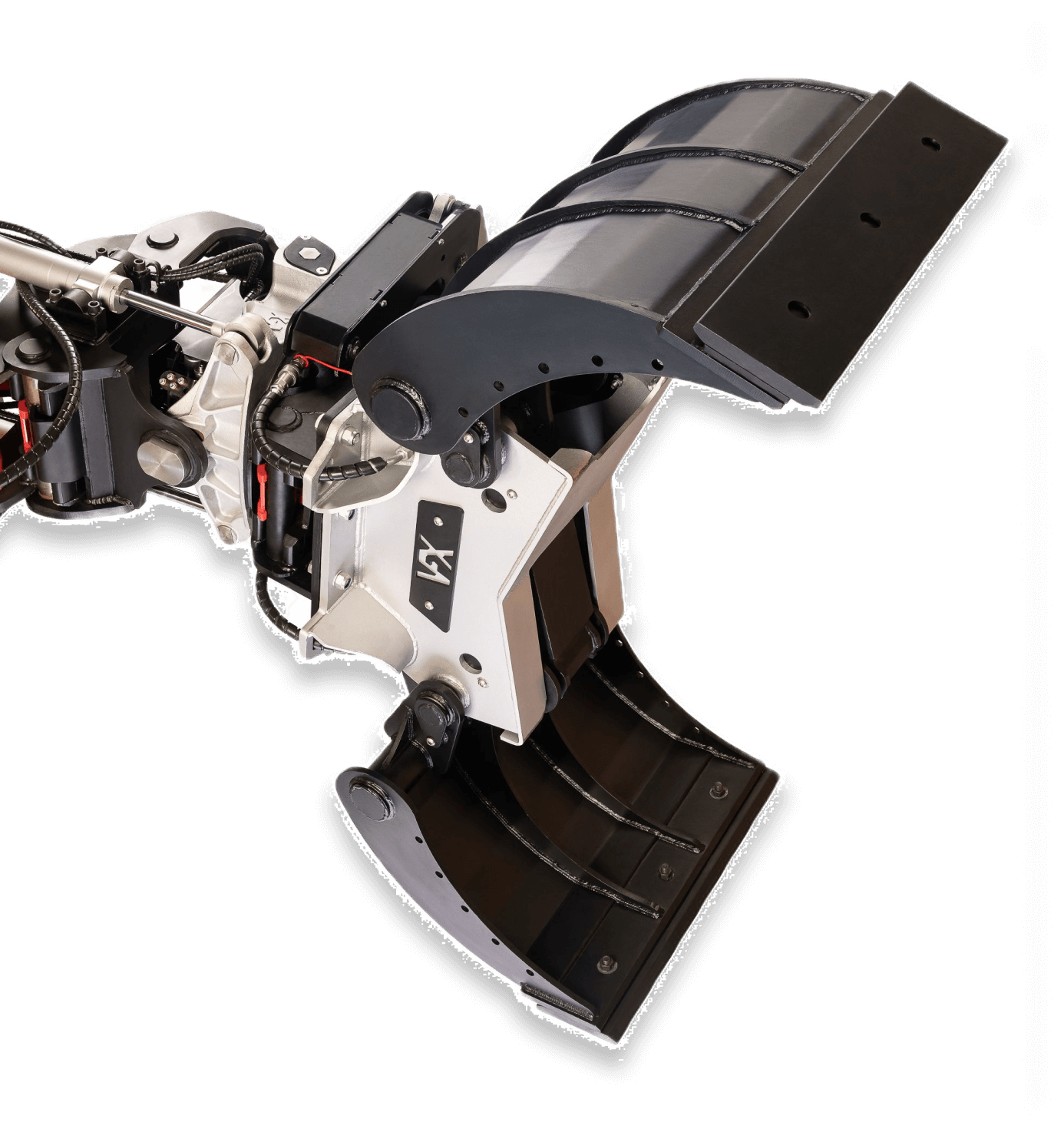

Incorporating a Tiltrotator from Versaffix into your operations offers substantial benefits. It unlocks new possibilities for your excavators, pushing boundaries across various industries and expanding the horizons of your business potential.

Contact Sales

Suitable for Your Industry

On railway lines where machine travel is restricted to straight-line movement, the need for additional manoeuvrability at the end of the excavator is crucial. Tasks like material removal between rails, banking, and manoeuvring sleepers are greatly enhanced with the use of a Tiltrotator. The ability for quick attachment changes and the reduction in operator fatigue contribute to heightened overall productivity, establishing Versaffix Tiltrotators as invaluable assets for railway maintenance projects that prioritise precision and efficiency.

In situations where roads require the maintenance of a single lane of traffic flow, excavators often operate in confined spaces. The enhanced movement provided by a Tiltrotator enables on-set track digging, efficient truck backfilling, and precise manoeuvring around features like kerbs, manholes, and pipes. The Tiltrotator’s versatility extends to a broader range of roadworks attachments, reducing the need for additional machinery at the roadside. This not only minimises traffic disruptions, safety hazards, and the number of machinery operators but also streamlines the quick and safe unloading of materials using fork attachments, this is especially beneficial in busy roadside scenarios.

On commercial and residential construction projects, space between buildings can be at a minimum in many cases as deliveries of materials can take up extensive space. Reducing the movements of the machine means less chance of colliding with materials such as rebar which can be extremely dangerous coming into contact with other people on site.

The added movement and gripper attachments allow the excavator to complete work that would usually be lifted or directed into place by a labourer. This prevents risk of harm to workers especially when materials are extremely heavy. Such instances include lifting and placing kerbs or concrete pipes or simply lifting heavy rocks or debris from trenches.

Digging precise foundations can be extremely valuable to space taken up on site. With added movement, the Versaffix Tiltrotator, is able to clean trench edges and batter the banks to reduce the risk of material falling which could upset the finish of the foundation or even cause an accident where a worker is inside the trench.

Lifting pipes or pallets of materials is made easy with the arm of excavator able to reach across obstructions that a teleporter is unable to and would traditionally need to move the obstructions to gain access.

The Versaffix Tiltrotator revolutionises landscaping by enabling the meticulous shaping of mounds and banks according to intricate design plans. This can often be accomplished from a single position, preserving existing landscaping. The Tiltrotator facilitates effortless positioning of rockery, sleepers, and returning blocks, eliminating the need for manual slinging and streamlining the overall landscaping process.

Unlock Versatility

Whilst a tiltrotator adds increased functionality in many areas, there are still some instances in which a tiltrotator does not benefit the end user. Tasks such as; heavy muck shifting or rock breaking.

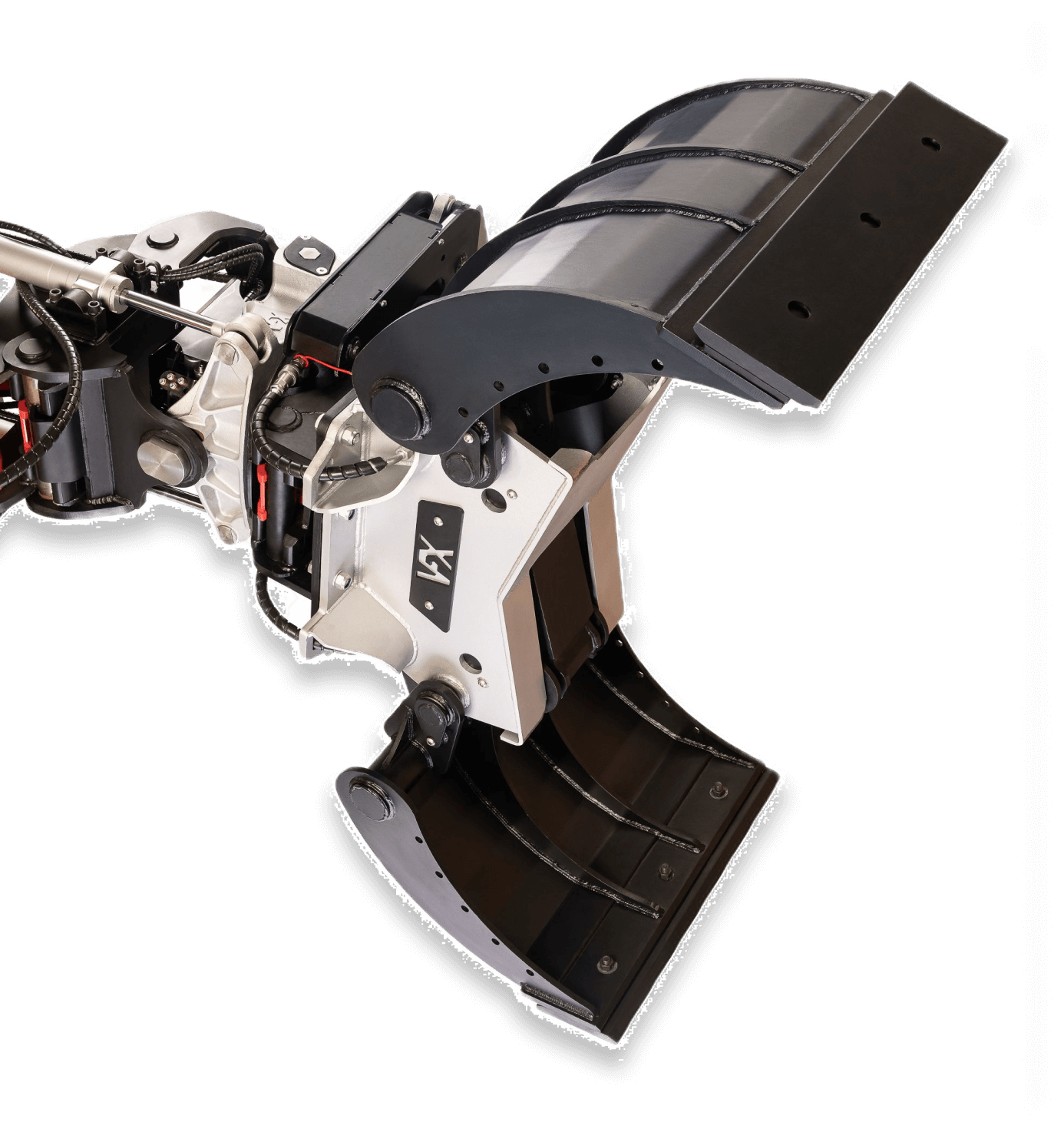

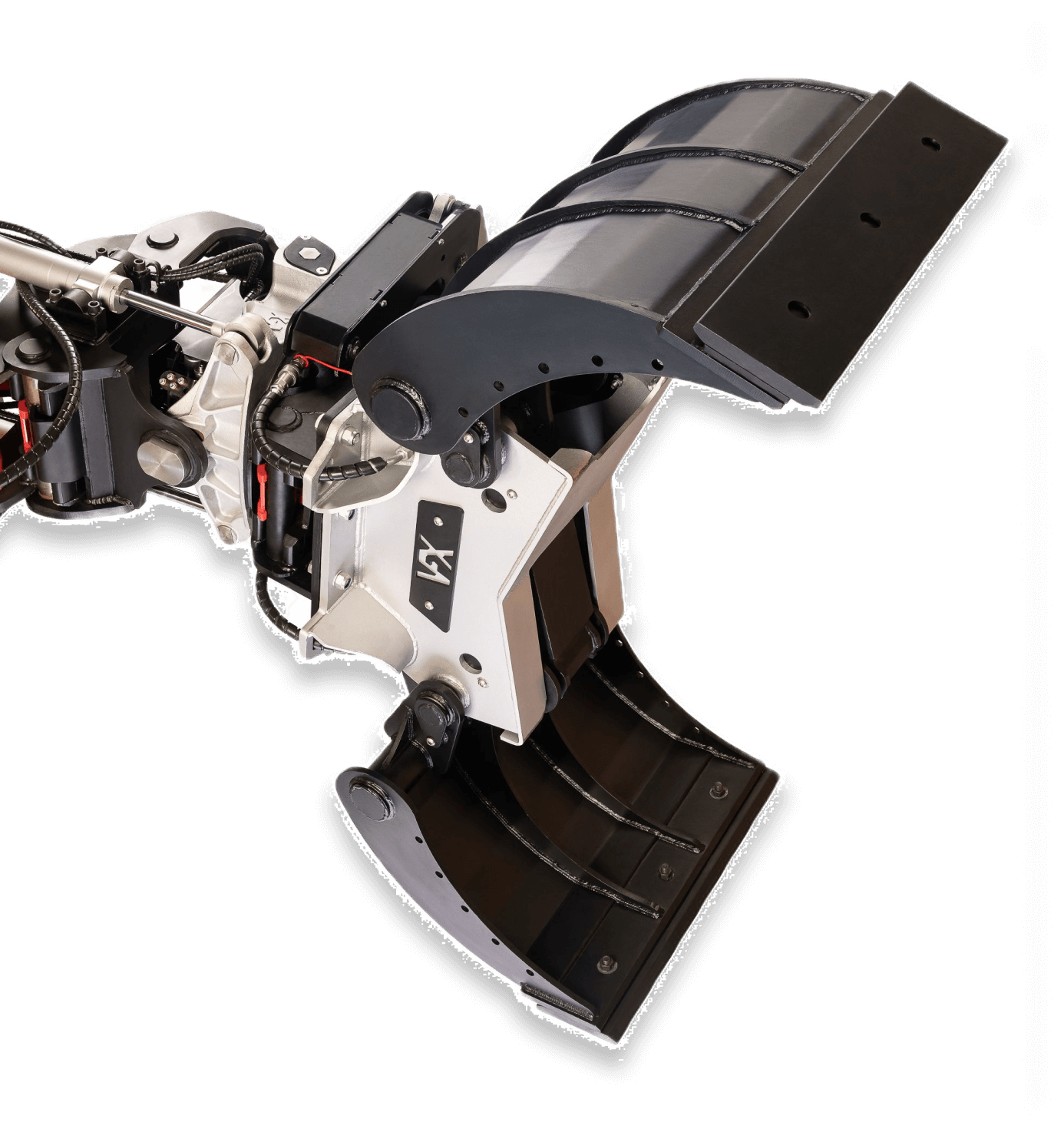

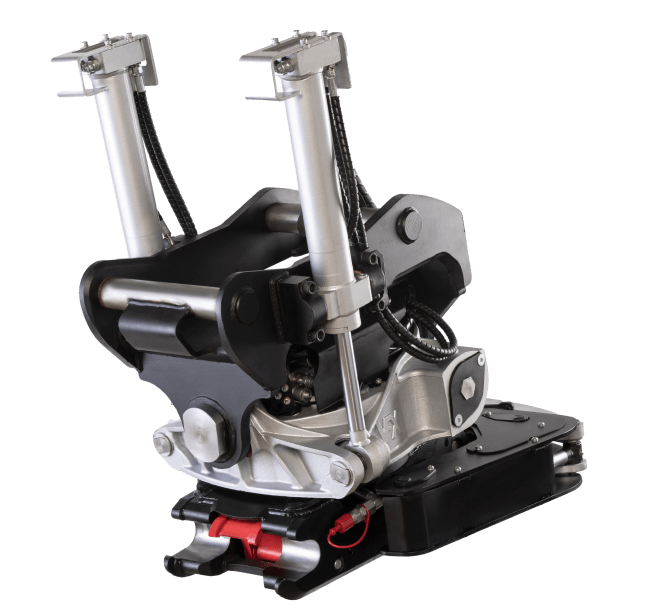

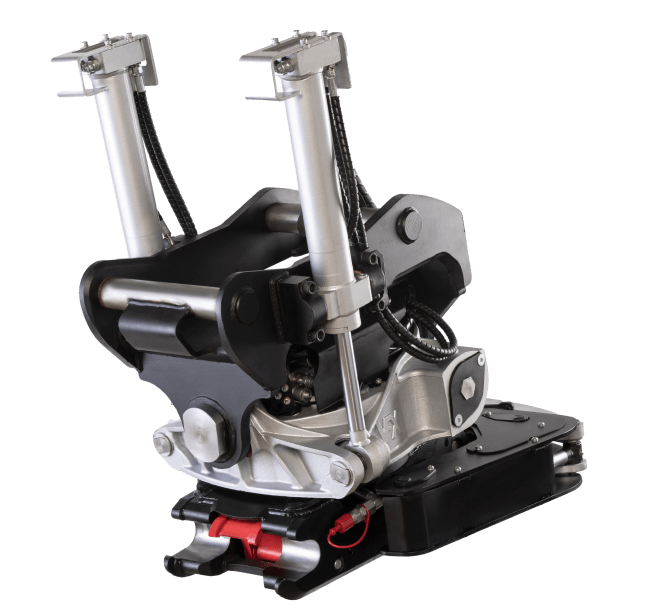

Versaffix accomodate these instances by providing a top coupler to allow the end user to detach the tiltrotator with ease. In comparison to traditional pin grabber style couplers breakout forces are increased with an S type coupler due to its compact design.

Excavators within the same weight class can now share the use of a tiltrotator when both are fitted with our control system and a top coupler.

Customers Receive Efficient Training

Upon the installation of our tiltrotators, we provide thorough training sessions to guarantee operators’ proficiency in utilising the equipment and mastering its additional features. Live demonstrations highlight the customisation options available, empowering drivers to make personalised adjustments in button layout, directional preferences, and rotation/tilt speed.

The fitting process is meticulously handled by highly skilled local experts, ensuring precise customisation of hose routing, fittings, and electrical connections tailored to your excavation specifications. For more information and to connect with your local expert, please don’t hesitate to contact us.

Service & Warranty

Our dealerships are well trained to provide a top-class service to meet customers’ needs in their area following the purchase of products. Versaffix provides a 2-year warranty on its products giving the end user peace of mind on their purchase.

A detailed user manual will be provided with every Versaffix purchase to aid the end user on the upkeep & maintenance of their product.